To spot weld the manifold shells together I need a fixture to hold the inlet ends properly spaced and in a line, so they fit to the cylinder outlets correctly.

My idea was to bolt some blocks of 1" steel to a piece of angle iron. I couldn't find 1" steel locally so I decided to use 3 piece of 3/8" steel instead. I didn't think it would take much longer to cut or drill 3 pieces than 1 thick piece. I bought a piece of bar stock 3/8" thick by 2" wide.

The Outlet openings on the cylinders are 1 7/8" wide by 1 1/8" tall. The shell material is .035" thick so I made the blocks 1 13/16" wide by 1 1/16" thick.

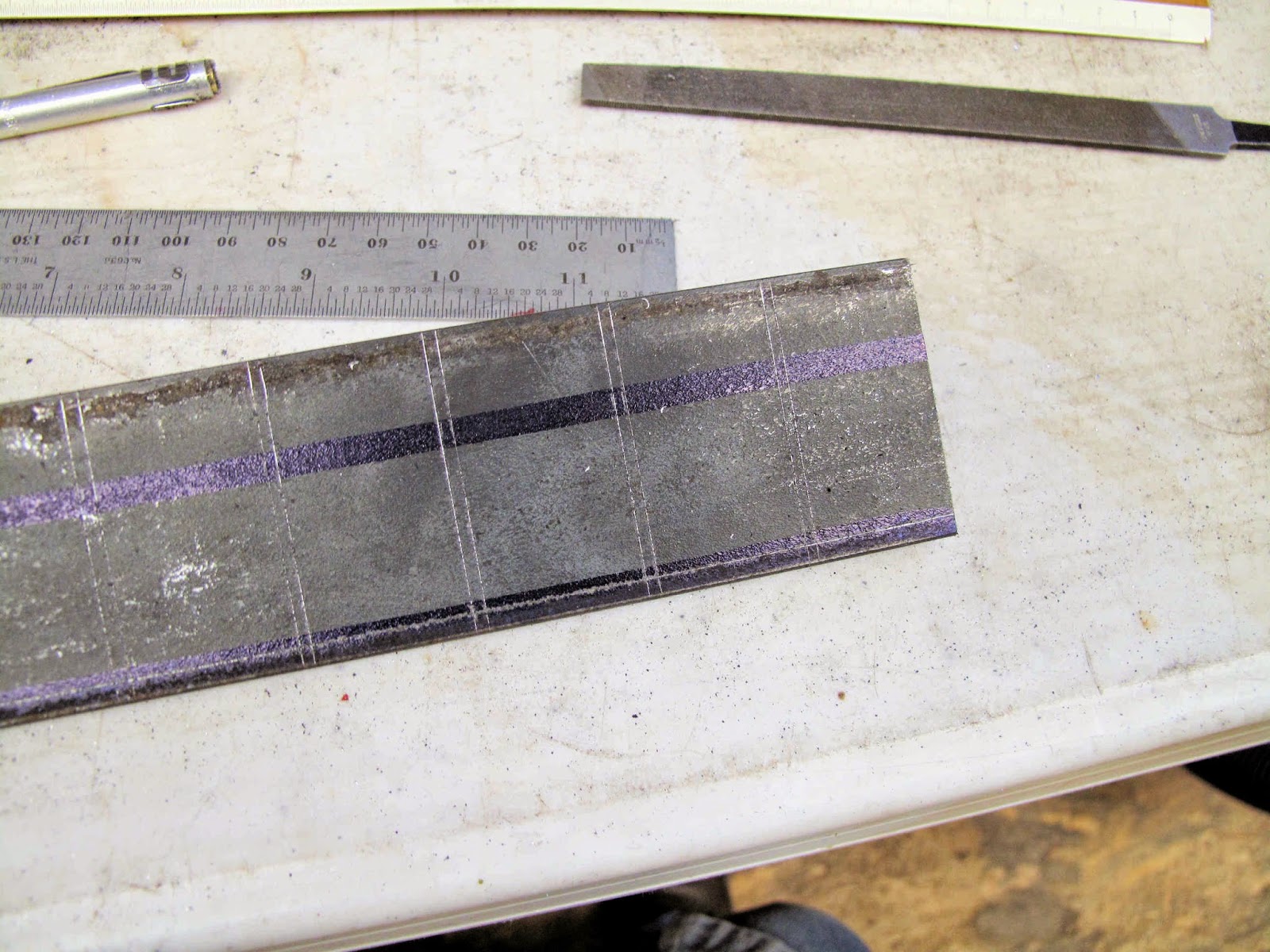

I find it easier to cut a straight line by laying out 2 lines to saw between.

I realized it would be easier to drill pilot holes in the blocks while they are part of the steel bar than holding them as individual small pieces. The pilot holes were drilled with a #2 (3/16") center drill until the sides of the drill just entered the bar. The center holes were then drilled through the bar with a 5/64" drill.

With the holes drilled the pieces were band sawed and the edges ground to the cut lines with the belt sander.

Four stacks of three blocks were aligned on the drill table with a square on the end. Clamps were applied to the hold the stack tight. Blocks and a clamp were added to the sides of the stack to keep the blocks aligned while drilling.

The holes was drilled in one end with a #12 drill, to get a tight fit to a 3/16" bolt. The bolt was installed in this hole with a nut and then the second hole drilled.

A bolt was installed in the second hole and then the clamps removed. The sides were then ground to even up the 2 sides opposite to the sides aligned at the start.

I also stamped marks on the ends of each stack to assure they get re-stacked in the correct order.

The sides were re-clamp and then one bolt removed to drill the hole to 3/8" for the bolt.

A 3/8" bolt was installed in the first hole and the second hole drilled.

I lightly ground the mating surfaces of the blocks and glued them together with super glue and clamped them with bolts in the holes to align them.

The corners were then radiused. The glue was just to hold the stack while grinding the corners.

I used a 24" piece of 1 1/2" x 1/8" angle iron. I scribed lines for the alignment of the blocks.

You can see it in the picture but I didn't notice it until I drilled the bolt holes, but block number 4 is to close to block 3. I had to drill new holes and move it to the right.

To locate the bolt holes I used a 3/8" duplicating punch in each bolt hole while holding the block in position.

To make holding the block easier I used the end of the square to hold the block 3/16" form the other side of the angle iron.

The holes were drilled with a #4-1/2 (3/8") center drill.

The blocks are bolted to the angle. They look long but I wanted the shank of the bolt to go through the block and through the angle iron. I used self locking nuts to assure they wouldn't shake loose while hammering on the shell inlets to fit them snugly to the fixture.

The fixture came out great but I realized I made the inlet openings slightly under size and they wouldn't on the blocks.

I'll fix the shell in my next post.

No comments:

Post a Comment